Differential Calorimetry

as a Method of Investigation of Chemical Accustic Reactions in the Real Time

Serbin V.V

In chemical technologies ultrasound methods of the chemical processes intensification are more and more used. Yet lack of information about the processes taking place under the ultrasound’s influence on reagents and impossibility to value the energy eliminated or absorbed in the process of reaction do not allow to rule the reaction during synthesis.

Today we value the participants of the reaction before and after the ultrasound’s influence. But we can neither follow the reaction at the moment of the ultrasound’s influence, nor value the quantity of energy given out for the sound chemical reaction (Exa) itself.

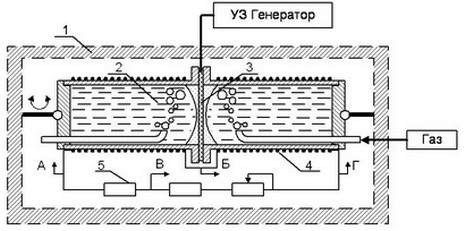

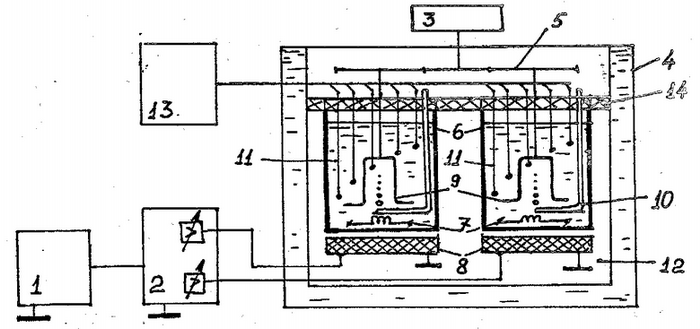

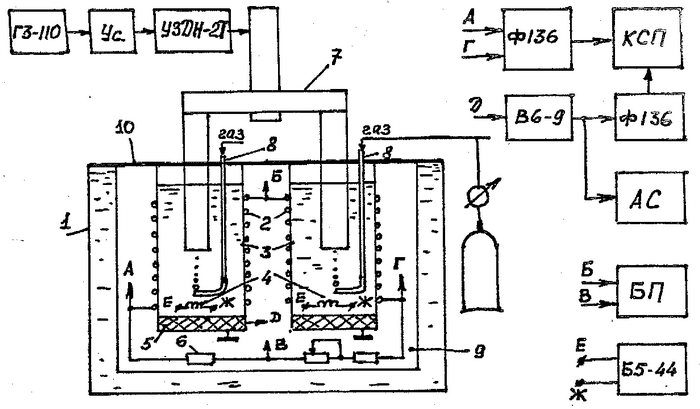

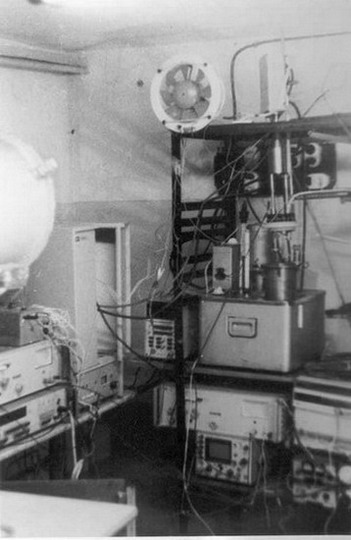

The author proposed the calorimeter (see p.1), where he attempts to, investigate the possibility to measure energy (Exa) for different gases, dissipated in water and the parameters of the installation itself as there has never been such an experience in the world’s practice. (Serbin V.V and others. Calorimeter for definition of chemical- acoustic efficiency in the water and non-water systems. Report at the conference “Cavitation-85”. Slavskoye. 1985.)

pic.1.

In the end of the long-lasted investigations a number of drawbacks, (which were not to overcome) in this construction was discovered. The possibility to measure weak signals on the ground of powerful noises is by all means the advantage of the differential system but it demands a particularly strict balance of such a system, i.e. stability of the base-line reproduction. In this construction it proved to be unachievable. It was learnt that by working peso ceramic warms and frequency shifts. As shift of frequency of ultrasonic emulators occurs each time unexpectedly, the process turns to be unrolled. The signal was supposed to be 10-15 μV, but the base line within 10-30 seconds .of the emulator’s work shifted by 100-150 μV both in plus and minus. Attempts to increase stability of generator and amplifier drove to nowhere. Registration with the help of thermo pairs, which are placed even in the size of the cell didn’t manage to work long either. First thermo pairs were not covered with glass and registered beside warmth sputter-ions which occurred with cavitations.

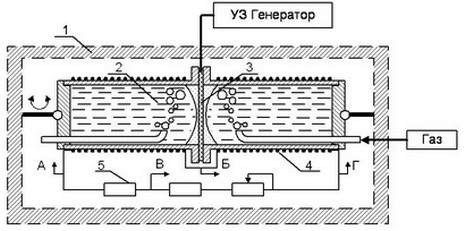

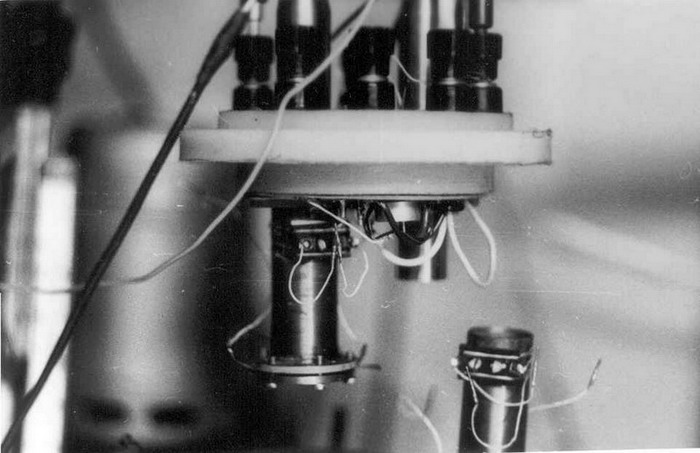

The glass coverage of the thermo pairs was destroyed by cavitations. Each piezoelement, as it occurred, has its own diagrammed of the emanation direction. This direction oscillated arbitrary which added instability. Besides, after each experiment the cells must be taken off for changing the liquid, which parameters changed during ultrasound emanation. The diagrammed can shift after installation. Beside necessity to take off ultrasound transducer by reparation and to install them again adds to instability of emanation. Attempt to measure warmth in the real system gas-water didn't give any positive results. Backing on our investigations we made global changes in the construction of calorimeter. The new construction is given in the picture 2.

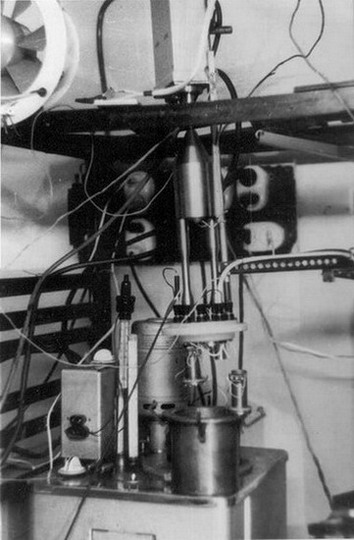

pic.2.

The base is standard ultrasound generator УЗДН-2T We use as leading generator a precise generator ГЗ-110 which allows to set discretely frequency with exaltedness 0,01 Hz Thus we increase stability of frequency. A special transducer allowed to solve the main problem- introduction of power from one oscillating systems into two cells. We had to rid out of mixer because of lack of place.

In the calorimeter’s nest (9) made of brass, on the lid, (10) made of Teflon two equal cells with thin walls are fastened (3).

The cells are made of brass; the walls are 0.3 mm thick. For the warmth registration thermo pairs of resistance (2) are used instead of battery of thermo pairs. These thermometers of resistance are non-inductively winded h the copper wire 0,03. The thermometers of resistance are turned on in the sides of the bridge, which elements (6) are placed on the lid (10) inside of the calorimeter’s nest (9) .This increases greatly stability of the base line. The bridge is connected with a specially made highly stabilized source of electrical currency. Calibration of Joule carried out with the help of the in-built heater (4), connected with the source of electrical currency. Б5-44.Electric currency is registered by digital ammeter B7-22A. Time is measured by the frequency-meter-chronometer Ч3-57 with exaltedness up to 1 mc sec.

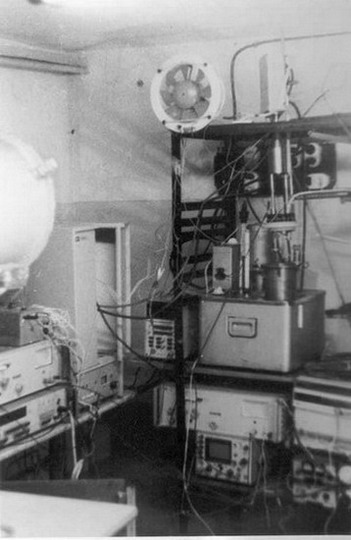

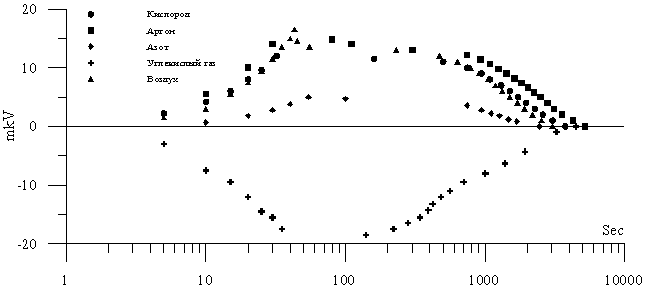

Turning the system in and out was made with the help of the timer. Calorimetric nest was immersed into thermostat U-10 with the supported temperature 25±0,05ºC. To saturate liquid with gas we led capillaries (8) into the cells. The signal was registered through amplifier F 136 on the two feathered self writer .To be sure that there is cavitations regime in the cell, cavitations sound was registered and analyzed. On this purpose microphones (5) are attached to the bottom of the cells. The signal of microphones was served through amplifier В6-9 to Ф136 and then to the second feather of self writer. From В6-9 the signal was served to analyzer of spectrum СК4-54 and photographed. The wished result was achieved. By sounding the same quantity of water in both cells during 60 sec the base line oscillates near 0.(see p.3). After turning off the ultrasound cooling happens synchronically to, which proves a good balance of the scheme. The measure of the sound speed in the process of reaction is for seen in the system as well. By S transducer = 0,2 sm2, W transducer = 6 Wt, V solution = 23 sm3, full warm effect proportional S under the curve for water, saturated with different gases, is given in the table.

pic.3.

| Газ | P, Дж | W, Вт |

|---|

| Кислород | 6.1 | 0.20 |

| Аргон | 9.2 | 0.28 |

| Азот | 1.6 | 0.05 |

| CO2 | - 7.0 | 0.21 |

| Воздух | 5.5 | 0.15 |

Sизлучателя = 0.2 см2, Wизлучателя = 6 Вт, Vраствора = 23 см3

It should be pointed out that after saturation of water with CO2 and emanation of the specimen with ultrasound a white film was found witch covered fully the surface from the wall of the brass cell till transducer. It is a substance which looks like paraffin. Evidently, in the water saturated with CO2 under the influence of ultrasound and in the presence of oxidized copper containing allays a reaction of foundation of carbon-hydrogen (paraffin) takes place. The latter is like mechanic-chemical reaction of of carbon-hydrogen’s synthesis on the copper catalyze held by the authors. (On synthetically oil out of CO2 and H2O. J.M. Paushkin, M.A. Koshevnic, G. P. Lebedeva. Academy of Sciences reports., 1992, volume 329,№1.)

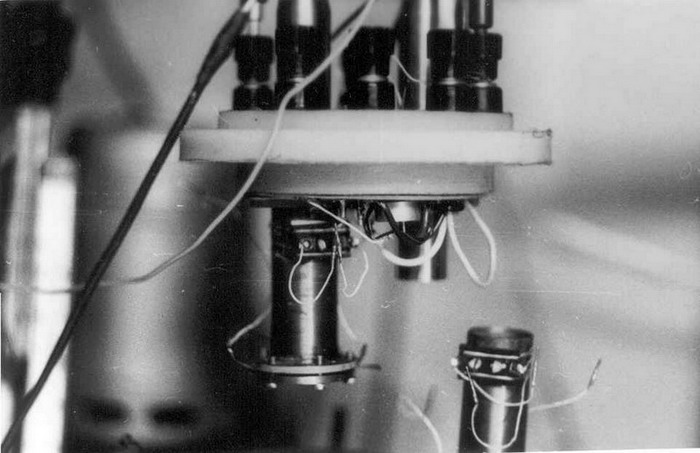

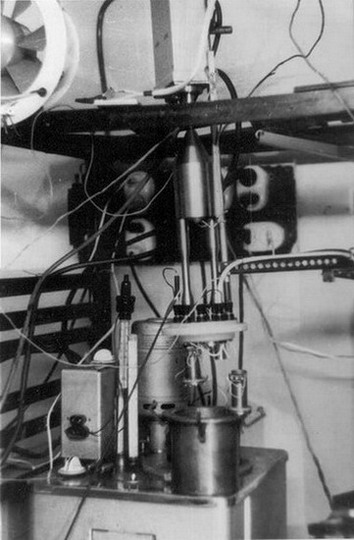

Because of new difficulties the author doesn’t have a possibility to go on the investigation. I would recommend to those who wish to continue the investigation in the following way. A horizontal calorimeter must be constructed (See p.4).

pic.4.

The model of such a calorimeter was constructed to check the principle possibility of the scheme’s work. Calorimeter was constructed on the base of demonstrative ultrasound generator with the working frequency f=2,5MHz with clear cells and focusing lenses built-in the bottom. In the horizontal set the qualitative colorful reactions were held, which happen in the ultrasound field and with cavitations only. Change of color of the solution now in the left then in the write cell proves the possibility of measurement in such a scheme. This scheme will let to take measurements on different frequencies. The simplicity of changing of frequency is in changing of piezoelectric ceramic transducer.

|